What is process mapping?

Any business activity can be described as a process if it goes through a series of steps and transforms inputs into outputs. The inputs might be raw materials, information, or human activity. The output is the finished product, document or anything that results from the series of steps.

A process map is a diagram that identifies all the steps in the process. Process mapping illustrates the flow of data or materials, the tasks, decisions, and relationships between the steps taken in the process. A good process map will define the starting conditions, the steps, the people involved, the final results, and can even be used to measure the success of the process.

Make your own process map with Gleek.

Every company or organization with complex processes will benefit from process mapping. Clearly understanding what is happening reduces the risk that changes to the process will cause problems. Optimization becomes easier, as does cost reduction. Even the onboarding of new employees can be improved when they can be shown a visual representation of what is being done and how they fit into the process.

Process mapping is even recommended by the ISO 9001:2015 of the International Organization for Standardization, which sees it as an essential tool for controlling quality management.

What are some types of process mapping?

The most basic process map is a flowchart. Even if you want to create a more complex process map, it can help to start with a simple flowchart that describes the essential steps involved.

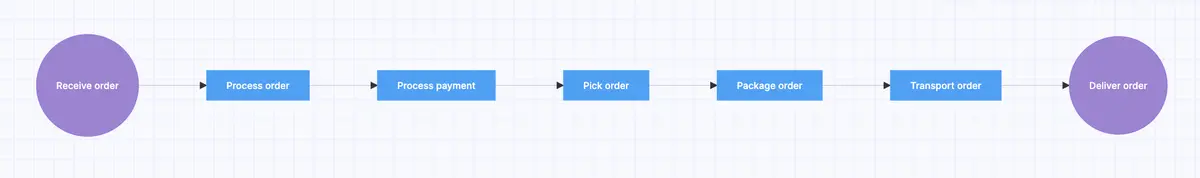

An example of a basic flowchart could be something like this for an online delivery company attempting to describe how customer orders are processed and delivered:

A basic flowchart can be either a high-level (or top-down) or detailed process map. The high-level map will only show the essential elements of the process, ignoring responsibilities and avoiding too much detail. The detailed process map does the opposite and shows the details of all processes and sub-processes.

An example of a high-level flowchart is a SIPOC process map. SIPOC is an acronym that stands for Suppliers–Inputs–Process–Outputs–Customers. A SIPOC process map is useful for working out inputs and outputs before starting a detailed map.

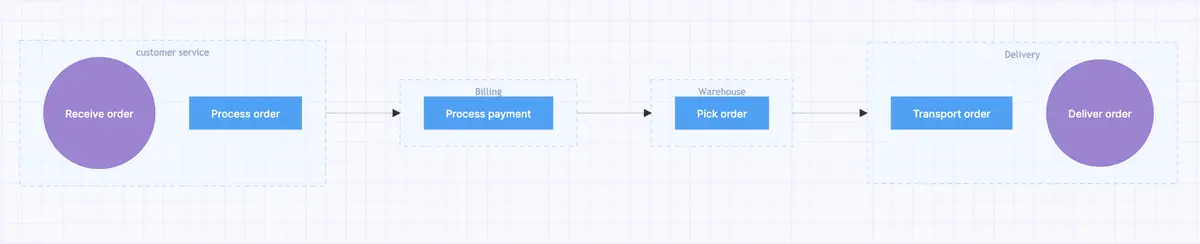

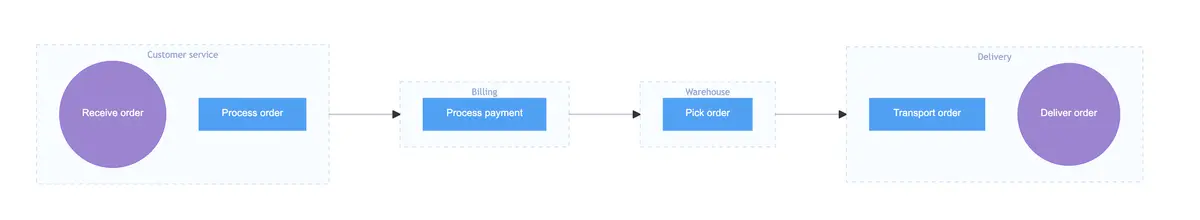

You can add more complexity to a basic map by including the people and departments who contribute to the process. This will extend your basic flowchart into a cross-functional or deployment flowchart (also known as a swim lane diagram, because it divides the steps into sections based on who is responsible). Charting the roles involved in the process enables you to show how it moves through the company and identify all stakeholders.

Our simple example above can easily be turned into a deployment flowchart:

You could drill down further into each step and identify sub-processes, increasing the complexity of the process map until you have completely described the activity. The above examples don’t include decision points, for instance, or what happens if something goes wrong, such as payment or delivery failing.

There are many other types of process map that deal with different approaches to describing a business activity, so it’s worth becoming familiar with them and choosing the correct one for your task. For instance, value-stream process maps differ significantly from value-chain process maps. A value-stream map shows how a core business process adds value to a product, whereas a value-chain map describes all the activities within the business that are performed to create the product.

How you can start process mapping

Creating a process map is a methodical exercise that rewards careful analysis of the process and all the steps involved. The steps described below should get you started, but make sure that you tailor them to your own situation and don’t miss an essential stage in your process.

If you find it hard to complete any of these steps, remember that brainstorming can be a good way to reveal the elements involved in your process. Get others involved and use a whiteboard or whatever you need!

1. Decide which processes you want to map. Where are the problems, weak points, waste, or high costs? What processes cause customer dissatisfaction? Can you automate parts of a process or reduce employee errors?

2. Work out where your process starts and ends so that you can define the scope of the process map.

3. What are the outputs? Do you need to list them all or can you leave some out?

4. What are the inputs? Remember that this should include everything from raw materials to tasks carried out by stakeholders.

5. Identify the people involved and determine exactly how they contribute in terms of inputs and tasks. You may need to carry out interviews or plan discussions to really find out just how everything fits together.

6. Start describing the steps that transform inputs into outputs. It will almost certainly take you multiple passes over the entire process before you’ve identified every activity, so don’t rush this stage.

7. Analyze and review your process map. Get all stakeholders involved and check that you’ve correctly described their roles.

8. Evaluate how well the process performs. You can now begin to determine how the process can be improved. This leads you to the real value of process maps – eliminating waste and optimizing the process to boost quality. Once you’ve identified areas of improvement, it’s time to create a process improvement plan and get fixing!

Fast and simple process maps in Gleek

You can use online tools or even just Microsoft Excel to create process maps, but we think that Gleek is a great match for creating high-level process maps. Gleek uses its own unique syntax to let you type your diagrams, so that you don’t need to waste time aligning shapes.

Even better – you can use Gleek for free and get started right away.

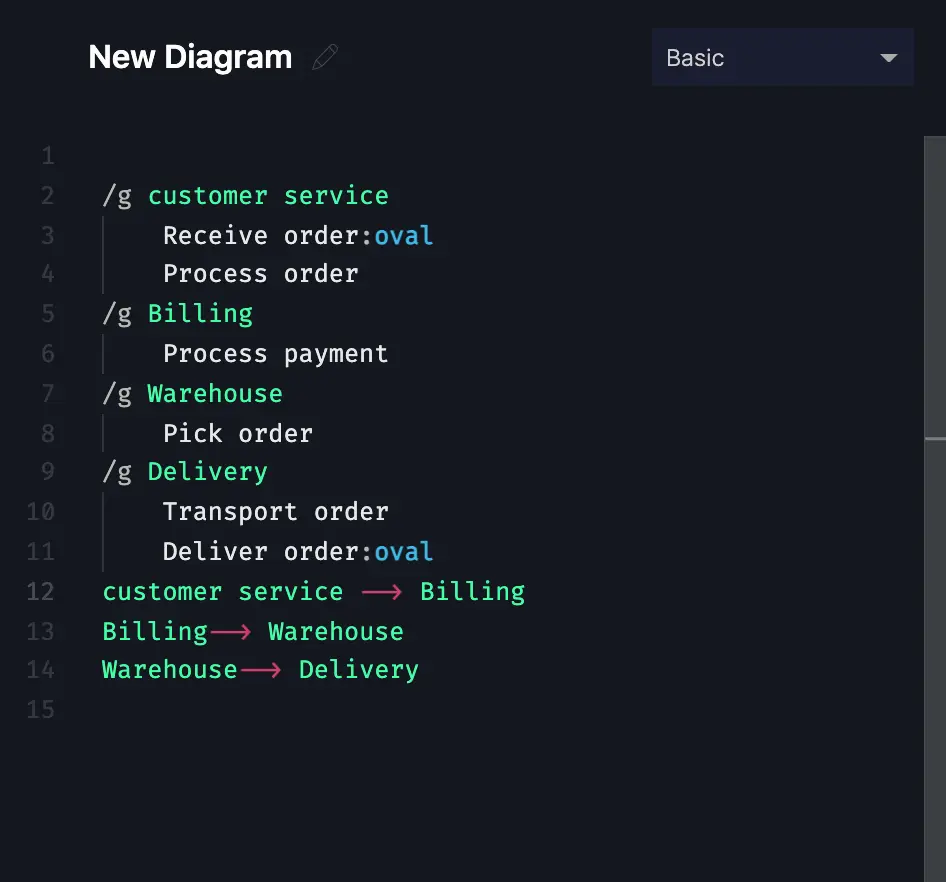

The two examples above, of high-level and cross-functional process maps, were both created in Gleek. It took just a couple of minutes to write out the code that was used.

Here’s the basic process map showing how the order is received and then delivered.

Make your own process map with Gleek.

And here’s the same diagram grouping into swim lanes showing which department is responsible for each stage: